Products

Authentic traditional brick and clinker cladding

Our product is a genuine brick or clinker tile cladding, combining a traditional beautiful brick surface with modern mounting technology. The cladding is manufactured under optimal factory conditions. The cladding is then mounted to the walls of the building using a mounting system, so it does not need to be supported by separate support beams. An efficiently ventilated facade ensures a healthy living environment long into the future.

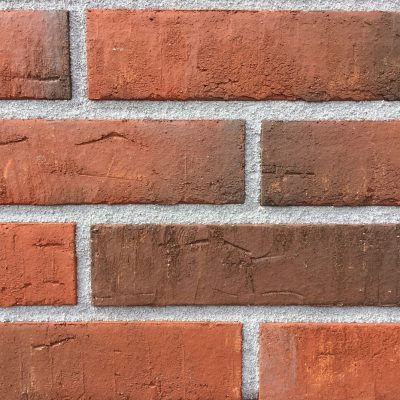

Classic

A cladding made of real brick tiles, reflecting traditional brickwork, with various brick options.

zero

Zero seam brick cladding made of zero-tiles sized 257×47. Easy to modify on site. COMING 2025

clinker

Cladding made of high-quality clinker tiles, with the possibility to engobe tiles before burning, to achieve wanted color.

cover

Seamless cladding from a wide range of cover tiles, which are fixed onto the mounting system on site. The cladding can be easily dismantled and reused.

Features

Traditional architecture

Our product is authentic brick or clinker architecture down to the details. Exterior corners, window mullions, etc. can be realized with corner tiles so that the original or desired architecture can be easily achieved.

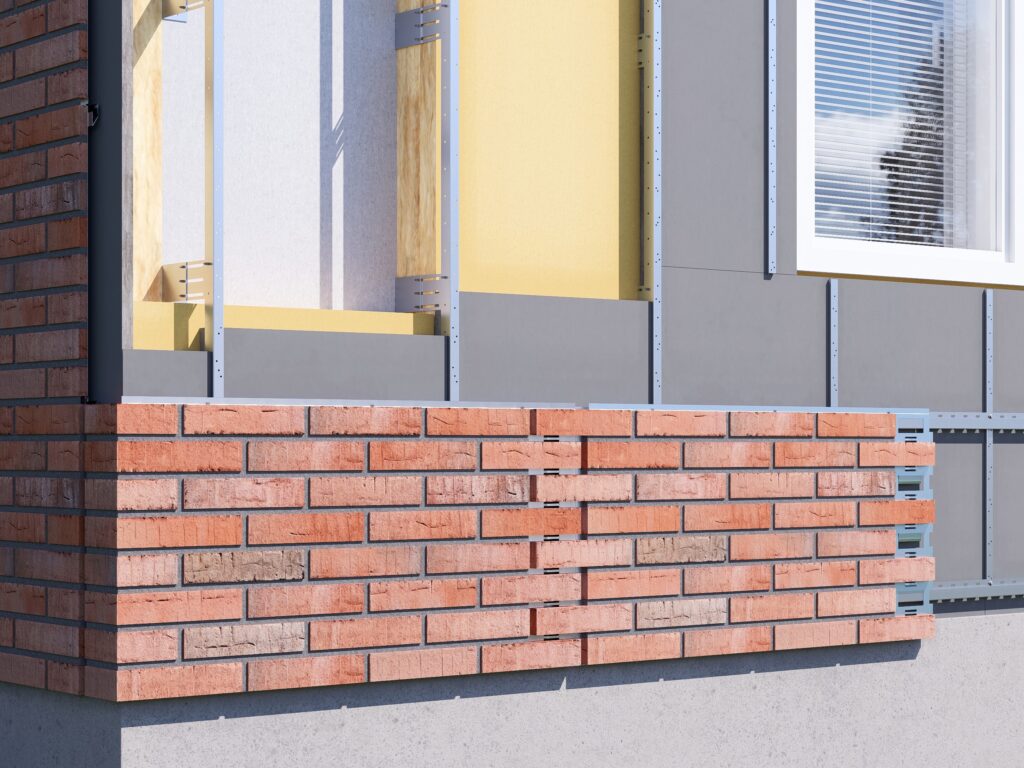

Ventilated facade

The brick tiles are integrated into the frame with seams, so our cladding is truly ventilated directly from the back of the tile. The minimum ventilation gap of a brick cladding is always 35 mm, which guarantees a moisture-proof wall structure.

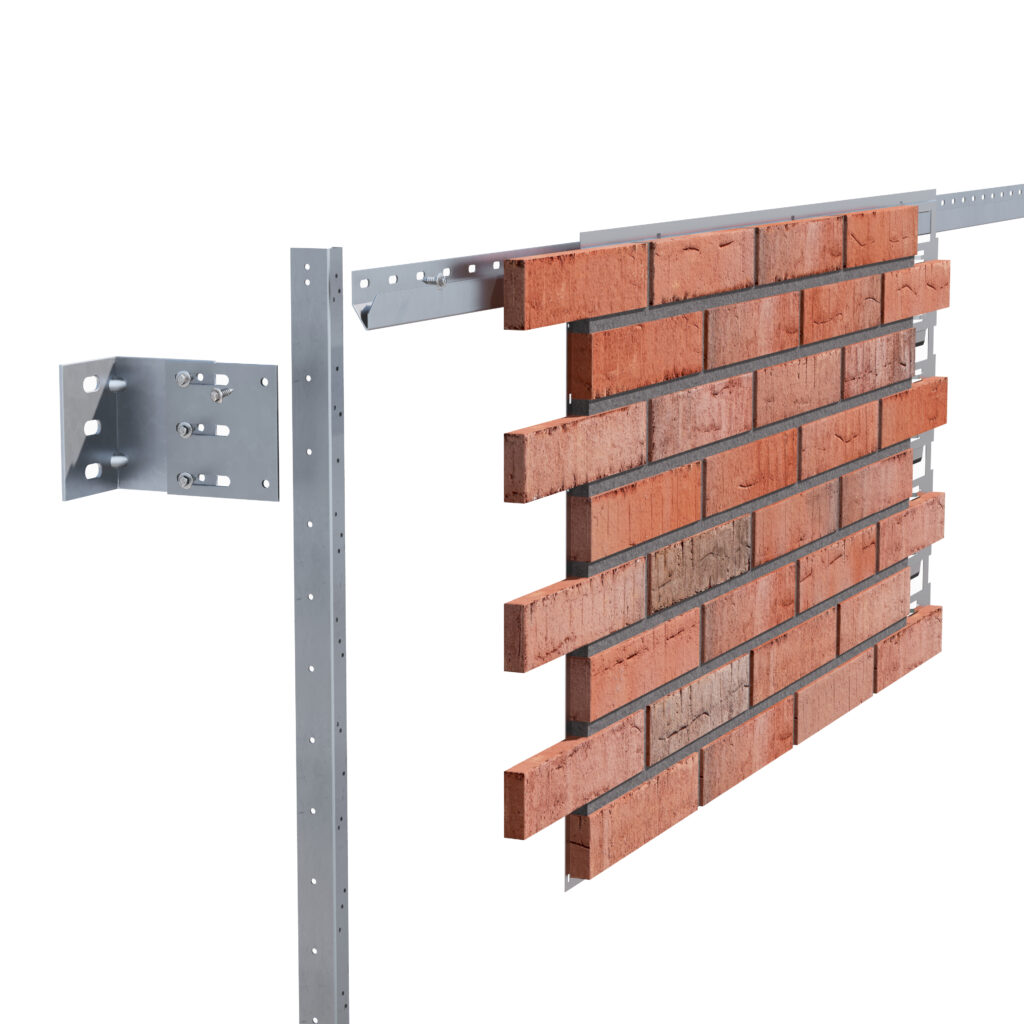

To be fixed to the back frame

The cladding is mounted on the wall using a customised mounting system. The system is fixed to the wall structure and no separate foundations or opening beams are required. The new cladding can also be installed on top of the old one.

Genuinely differentiated from the body

Can be used with different frame materials, as the cladding is not mechanically attached to the frame at any point, but hangs on mounting rails, allowing it to survive temperature variations.

Advanced mounting system

The cladding panels are mounted on the wall using a customised mounting system. The type of mounting system is chosen to ensure that installation is as efficient as possible and best suits the needs of the site. The simplest mounting system is a cold system. In the case of insulated walls, an insulation system is used, which can contain up to 250 mm of insulation. The insulation system can also be used to level the walls, as the system offers a margin of adjustment. This has particular advantages in renovation work, where the backfill is rarely flat. Wall and extension brackets are selected according to the required structural depth of the insulation system.

Ask more

Project-specific manufacturing

Brick cladding is always made on a project-by-project basis. The product is designed to the dimensions of the façade using a CAD application. The cladding plan shows the positioning of the cladding panels on the façade and also serves as a work instruction for the installers. The panels are manufactured according to the plan and delivered to the site, packaged by wall area.